Seulachadh adhartach

Nuair a tha cuideam air an leaghan gluasadach, gas, gas, duslach agus meadhanan eile san loidhne-phìoban, tha cuideam na lib reulainn ceangailte ri uachdar a 'chuirp na pìoba cuideachd. Le taic bho structar an inneal, tha a-mhàin gu bheilear a 'bacadh air a' mheadhan anns a 'mheadhan anns a' phìob, ach tha coileanadh seulachadh iomlan na pìoba.

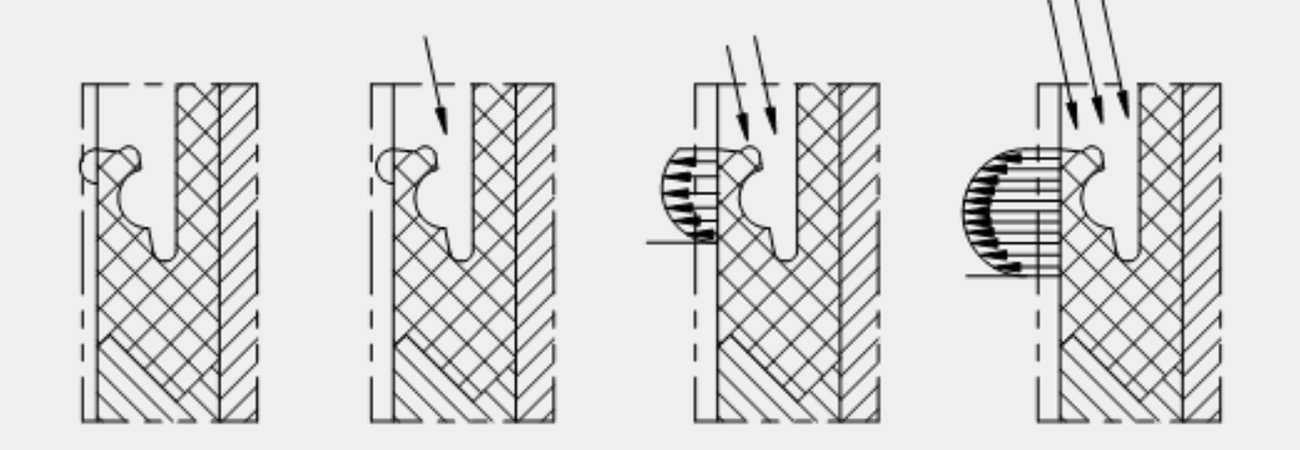

Aig àm teannachadh, a rèir prionnsapal basgag de chlò-bhastan, a rèir cùis a tha co-ionann ris a 'mheadhan, agus mar sin tha bonn na rip air a dhlùthadh Tha e air a dhlùthadh gu tuath, tha an talamh conaltraidh eadar an loidhne geuise agus an loidhne-phìoban air a leudachadh, agus tha an cuideam conaltraidh air a mheudachadh, mar a chithear ann am Figear1.

Fo gnìomh cuideam, tha dlùth cheangal aig an uachdar ròin agus an loidhne-phìoban sin, a dh 'fhaodadh dèanamh cinnteach gu h-èifeachdach air na ròin. Tha e ri fhaicinn bho na fìor chumhachan obrach a tha an ròin ròin mar as trice ròn statach sa mhòr-chuid tha an suidheachadh obrach cruaidh agus crathadh beag crathadh agus buaidh. A rèir feartan ròn Y-co-theacsa, faodaidh an cearcall ròin a bhith a 'giùlan seula fiùghantach de chòrr air 20mpa.

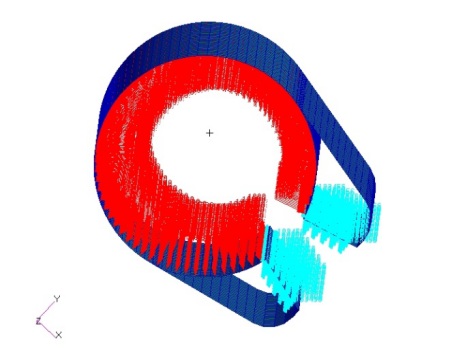

Is e an slige am prìomh chuideam le pàirt den neach-ceangail loidhne-phìoban, a tha gu dìreach a 'toirt buaidh dhìreach air sàbhailteachd agus earbsachd an fhìor chleachdadh. Feumar anailis measaidh structarail eadar-dhealaichte a dhèanamh gus faighinn a-mach a bheil neart de gach puing cuideam fo chuideam obrach fa leth, faigh a-mach atharrachadh agus leasachadh co-fhreagarrach, gus dèanamh cinnteach gu bheil iad a 'dèanamh cinnteach à sàbhailteachd agus earbsachd.

Tha neart an t-slige co-cheangailte ri neart còmhnaidh, ductity, tiugh agus feartan eile de na stuthan a chaidh a chleachdadh. Bidh feachd clamping nam boltaichean ag adhbhrachadh sònraichte den t-slige. A bharrachd air an sin, bidh bileag an t-slige cuideachd a 'dèanamh a-mach fo chuideam. Is e na factaran sin nam feartan a tha a 'toirt buaidh air seasamh cuideam, sàbhailteachd agus earbsachd an t-slige.

Gheibhear modail eileamaid an eileamaid den shligean, mar a chithear ann am Figear2.

Aussachd tarraing-a-mach adhartach.

An dà cheann a 'cho-chladach a' gabhail ris an structar CLASP innleachdach. Às deidh an stàladh, bidh an CLASP air an t-seòrsa fiacail a 'cur air adhart gu teann uachdar na pìob. Nuair a bhios an cuideam am broinn a 'phìob a' meudachadh no bidh an fheachd axial a 'meudachadh mar thoradh air buaidh feachd bhon taobh a-muigh, bidh an CLAPT a' teannachadh a 'bhuidheann a' phìob

Ùine a 'phuist: Jun-17-2020